If you still have questions after you read it, please click the QR code to enter the high-conducting potty adhesive small video in the shake number, which can more intuitively see the whole picture of this product.

Performance characteristics

● High heat transfer, thermal conductivity is 1.5 w / m · k;

● Low viscosity, as low as 4600 mPa · s, good fluidity, good fill, and faster bubbles after pnery;

● Excellent flame retardation performance, reaching V0 level;

● Elastomer, good anti-shock impact and deformation ability;

● -50 ° C ~ 200 ° C can maintain stable physical mechanical properties for a long time,

● With blanking, the components after potting can be repaired and replaced;

● Curing, heating to 85 ° C, can be completely solidified, and improve work efficiency is improved.

Typical use typical application

For more power supplies, such as fast charge, large watts.

technical parameter

|

state status |

Test items |

unit |

parameter parametric |

Remark remark |

|

Before curing |

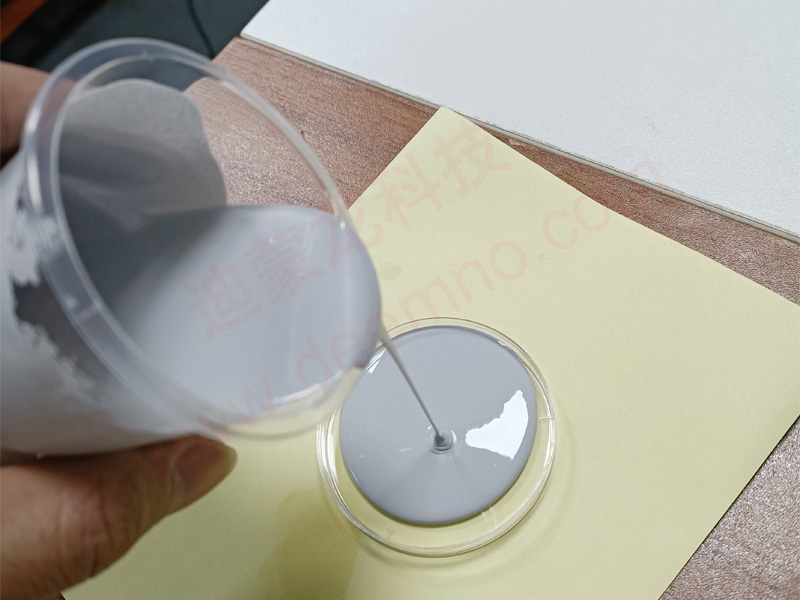

color |

|

grey gray pessimistic |

A component |

|

White white |

B component |

|||

|

Viscosity |

25oC, MPA S |

4500 ± 1000 |

A component |

|

|

4800 ± 1000 |

B component |

|||

|

density |

25ºC,g/cm3 |

2.40 ± 0.2 |

A component |

|

|

2.40 ± 0.2 |

B component |

|||

|

The mixing ratio |

|

1: 1 |

||

|

Operating time |

25ºC RH 50%, min |

|

||

|

Curing time |

25ºC RH 50%, HR |

|

||

|

85ºC,Hr |

|

|||

|

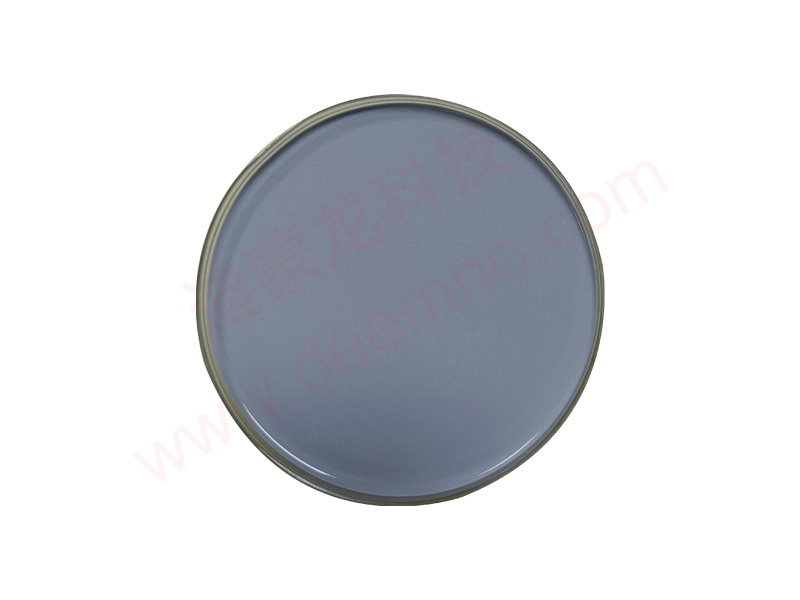

After curing |

color |

|

grey gray pessimistic |

After mixing |

|

hardness |

Shore A |

35 ± 5 |

||

|

Thermal Conductivity |

w/m·k |

|

||

|

Dielectric constant |

1.2MHz |

3.0 ~ 3.3 |

||

|

Dielectric strength |

Kv/mm(25ºC) |

|

||

|

Volume resistance |

(DC500V), O. CM |

1.0 × 1014 |

Instructions

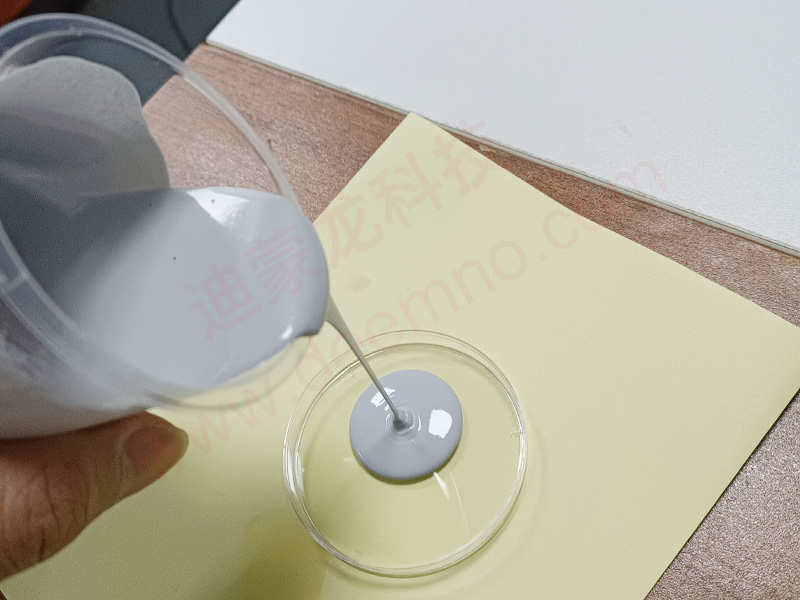

Mix

The product is provided in two-component form, producing a small amount of precipitation during transportation and storage, should be pre-stirred before use. After a component is thoroughly mixed with B components, gently agitate to reduce the amount of air mixed. Vacuum sputum treatment before perfusion can reach the most ideal rolled state.

2. Applicable period / operation time

The curing reaction starts at the beginning of the mixing process. The initial curing phenomenon is gradually increased, and then the gel is started, and then transformed into an elastomer. The definition of the applicable period is that the viscosity increases to the original twice as component A and B (mains and curing agents).

3. Processing and Curing

After the product is fully mixed, it can be directly injected / dispensing to a component that requires curing, and the components should be vacuum-deprived after using the product pot. The product can be cured either at room temperature (25 ° C) or heated.

4. Temperature range available

For most applications, the product can be used in a temperature range of -50 to 200 ° C.

5. Compatibility

In some cases, this product will not be able to achieve the most desirable curing effect when contacting some plastic or rubber, and the surface of the solvent is cleaned or baked with a slight baked above the curing temperature can be resolved.

Some chemicals can inhibit curing, and the following materials should pay special attention: an organic substance containing N, P, S, and an ionic compound containing Sn, Pb, Hg, Bi, AS or the like; compounds containin enhance the adhesion, combining the repaired materials with existing pottings.

7. Operational precautions

1.a, b Components must be stirred after 2-5 minutes after opening the original package, avoiding the effects of product effects due to the layered precipitation caused during transportation and storage.

2. When mixing, consolidate agitation, especially the stirring;

(5) Storage and validity period

When there is no open seal below 25 ° C, the product from the date of production is 6 months. If it is overdue, it can be used normally after test inspection.

(6) Packaging specifications:

25kg / barrel;

Shenzhen Dimenglong Technology Co. , Ltd.

Address: Building 1, Block C, 2nd floor, Huiye Science and Technology Park, Guanguang Road, Tangjia community, Fenghuang Street, Guangming District, Shenzhen City