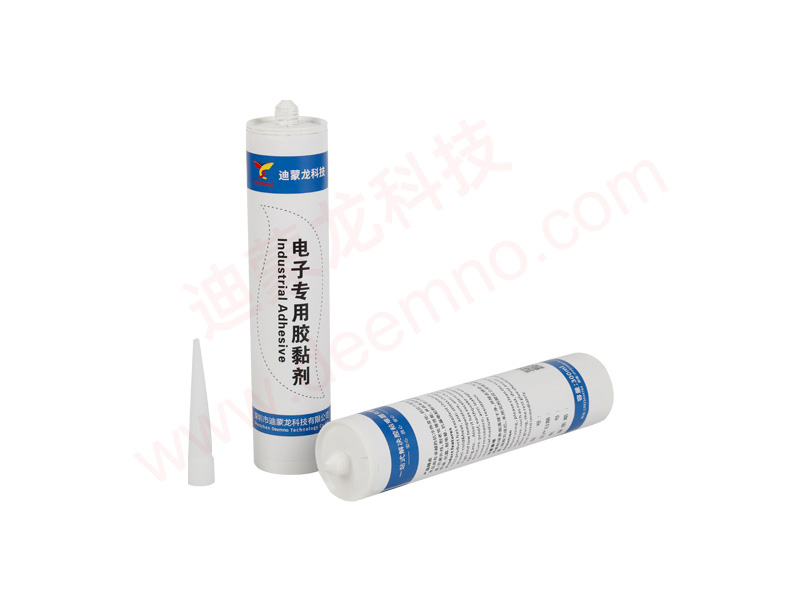

This adhesive is made of silicone composites, fast drying time, single component, open tube, easy to use. Semi-flow, automatic leveling, self-cupping, cupping after solidification, plaguing the sealing insulation, suitable for occasion, high-resistance, temperature resistant (-60 ∽200oC) performance.

(I. Overview:

This product is a silicone composite material, which is neutrally cured by contact with moisture in the air to become a flexible rubber-like solid. This product has a wide applicable temperature range (-60∽200ºC), and is suitable for various metals and Non-metallic materials have good adhesion properties. This product is mainly used in products with weather resistance, temperature resistance, moisture resistance and antifouling requirements. It has excellent electrical properties and strong aging resistance. Especially suitable for dust-proof, moisture-proof, waterproof and insulation protection of electronic products.

If you still have questions after reading it to the end, please scan the QR code at the bottom to enter the Douyin account to find the small video of the glue coating, and you can see the whole picture of this product more intuitively.

(2) Technical parameters

|

state |

Test items |

unit |

parameter |

Remark |

|

solid change forward |

color |

--- |

White |

|

|

Exterior |

--- |

half flow |

||

|

density |

25ºC, g/cm3 |

1.2±0.1 |

||

|

Dry time |

25ºC, RH: 55%, min |

3-10 |

||

|

full time |

25ºC, RH: 55%, h |

twenty four |

||

|

hardness |

Shore A |

25-45 |

||

|

solid change back

|

Thermal Conductivity |

w/m k |

0.20 |

|

|

Coefficient of expansion |

µm/(m,ºC) |

≦200 |

||

|

Elongation at break |

% |

≥50 |

||

|

tensile strength |

MPa |

≥0.8 |

||

|

Shear strength |

Mpa-Aluminium/Aluminium |

≥0.8 |

||

|

Dielectric strength |

Kv/mm(25ºC) |

≥18 |

||

|

Volume resistance |

(DC500V),Ω·cm |

1.0×1014 |

(3) How to use

1. Substrate cleaning: remove oil stains, dust, rust, etc., and make the sizing surface clean and dry.

2. Sizing: Apply the glue to the gluing part of the corresponding substrate manually or using dispensing equipment.

3. Curing: This product is a moisture-curing material. Its surface drying and curing speed depend on the relative humidity, temperature and thickness of the glue (2mm) in the environment where the material is used. Generally, it is under the conditions of 25ºC, RH: 50~60% It can be put into use after curing for 24 hours, and reaches the best design performance after 7 days. The surface dry time will be extended with the storage time. Generally, the surface dry time can be maintained within 3 to 10 minutes within 3 months from the date of production. Please use it with caution when it exceeds 30 minutes.

4. Precautions: After opening, the unused glue should be sealed and stored immediately. When using it again, if there is a little crust on the seal, it can be used after removing it without affecting the performance of the glue.

(4) Storage and validity period

Store unopened at 25°C away from light, and the product has a shelf life of 6 months from the date of production. Because the product is solidified by reacting with the water vapor in the air, it must be sealed and stored when not in use; after a long storage time, the bottle mouth appears delamination, which is a normal phenomenon and does not affect the performance; if it is overdue, it will pass the test and inspection can be used normally.

Shenzhen Dimenglong Technology Co. , Ltd.

Address: Building 1, Block C, 2nd floor, Huiye Science and Technology Park, Guanguang Road, Tangjia community, Fenghuang Street, Guangming District, Shenzhen City